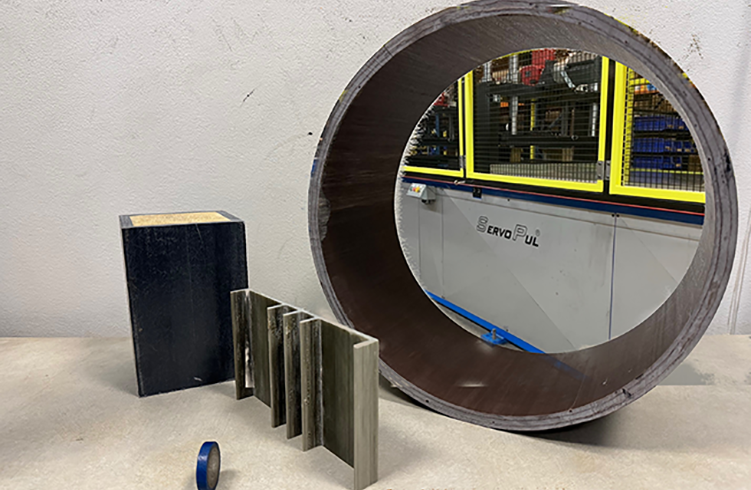

Fiberglass pultruded flat panel/sheet can be used alone or in combination with other materials, such glass fiber reinforced plastic sandwich panels, fiberglass reinforced plastic honeycomb panels, it’s mainly used in the field of logistics, furniture, decoration, home & other fields.

The fiberglass reinforced plastic sheet has excellent impact resistance, it is the ideal material for roofing as well as fiberglass floor plate & widely used in construction, municipal engineering facilities, billboards, office and living partition, industrial protective cover, elevated road noise screens, ceiling lighting. Strong characteristics are that it's high strength with light weight, long life span, corrosion resistant, fire retardant & low maintenance.